CO2 reduction through in-house power generation

Plastic injection molding is an energy-intensive production process and therefore has a high electricity demand. Gebr. Schwarz GmbH is very aware of its responsibility to reduce CO2 emissions and started investing in alternative power generation at an early stage.

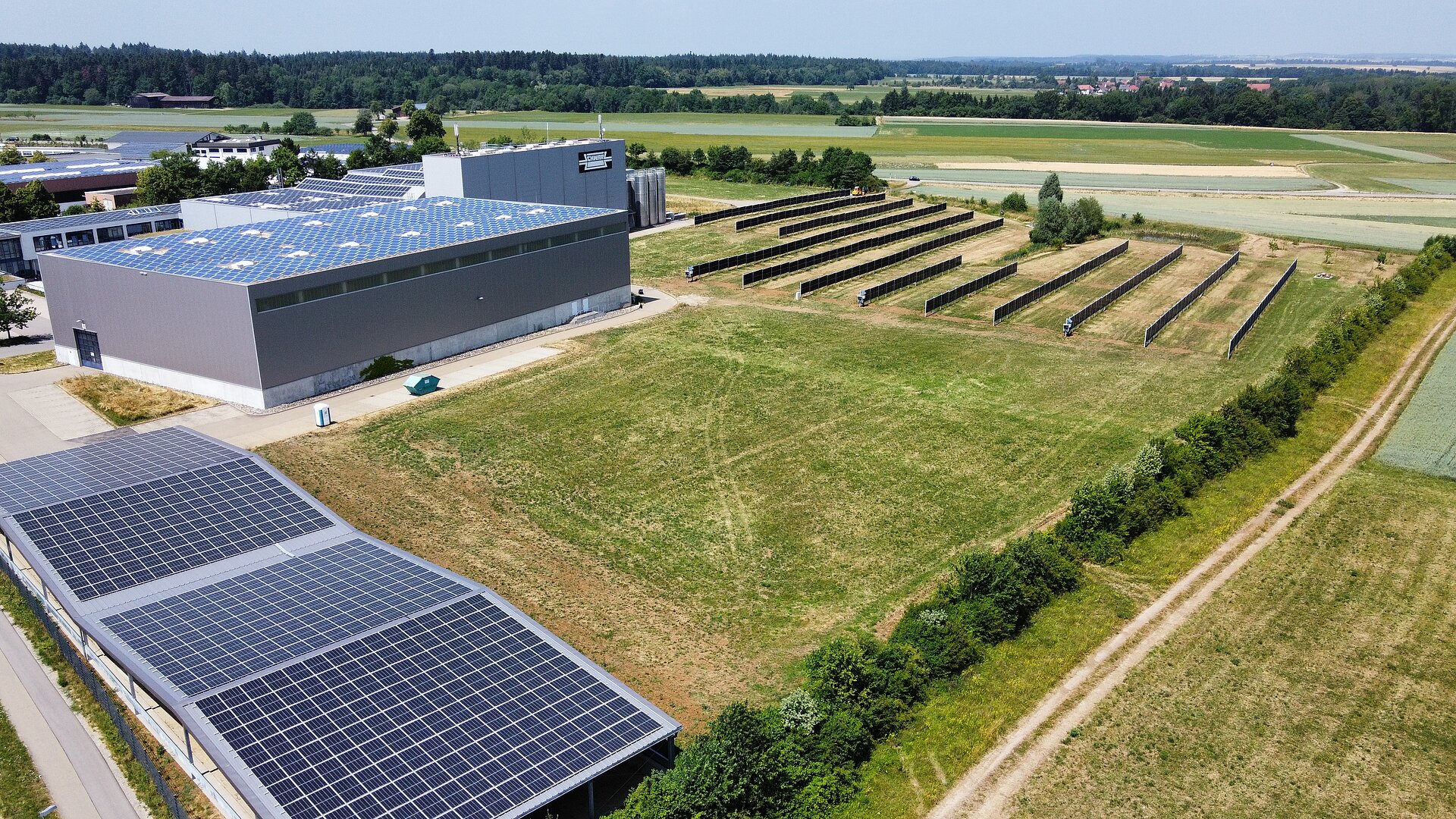

After all roof areas were equipped with PV modules in the years 2014 - 2018, a part of the parking lot area could be roofed over and also equipped with PV modules in April 2023. In this course, 22 E-charging points for visitors and employees of SCHWARZ were also installed.

The third expansion stage of our transformation concept will go online in the next few days. This refers to a vertical open space PV system with bifacial modules to take advantage of the flat sun in the morning and evening. With these three PV systems, we have a capacity of 1,100 kWp and will thus cover 40% of our electricity needs with green

The next step is already planned. In order to also make better use of the flat sun in the winter months, a façade PV system is planned on the south side of our warehouse.

This will make the best possible use of SCHWARZ's land for power generation. But it should not stop there, we want to use further alternative energy sources to reach our goal of being self-sufficient with "100% green electricity" by 2030.