Reach your goal faster through efficiency

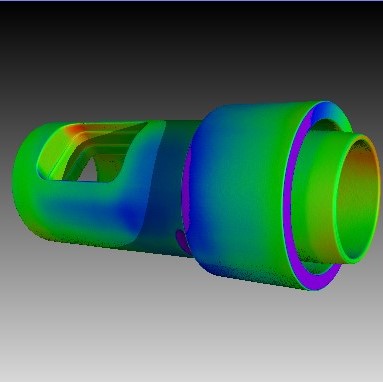

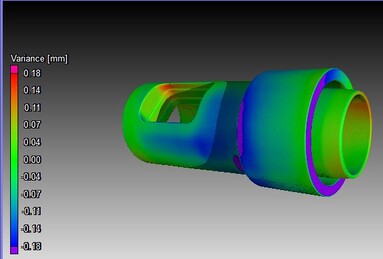

Optical measuring methods are non-contact measurements and open up new possibilities for the qualification of articles with complex geometries. At Gebr. Schwarz, 2 main measuring methods are used, stripe light image (from GOM) and CT (computer tomography). These are used to generate scan data of the components within a very short time, which enable a comparison of shapes and surfaces with the CAD model.

The measuring method used depends on the requirements and the application. With the CT method, the test components are "X-rayed", so that blowholes in the material or very deep boreholes can also be determined. The GOM process is a fast and cost-effective method to generate the so-called false color image. Both measuring methods can also be used to generate false-color images and thus gives a quick statement about the geometry.

Stripe light projection (GOM) is the more economical measuring method due to the lower invest costs of the system. For components with metal inserts, the method also offers more possibilities, as the reflection of the metal insert is not important compared to the CT method. For smaller objects the CT measurement provides better results, while for larger objects the stripe light projection is brilliant. Compared to the CT measuring method, the stripe light projection has clear disadvantages for holes and inclined recesses, because it can only scan 3D objects that are within its direct field of view.

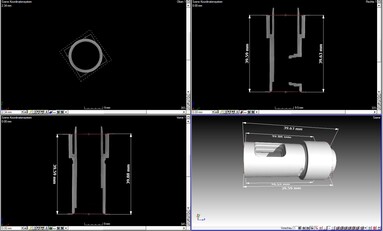

At Schwarz, these techniques are mainly used for first article inspection and qualification. This means that an initial statement about component deviations can be made very quickly in order to initiate possible tool corrections. Subsequently, only a few areas need to be checked with more complex tactile measuring methods.

But these procedures are not only justified in quality assurance. In our toolshop and design departments, 3D models are also generated via point clouds and reverse engineering. An added value that we offer our customers when no drawings or 3D models are available. This shortens your development times and makes your work even more efficient!