3D printing – established at SCHWARZ

The history of 3D printing is older than many think. The 1980s saw the birth of 3 major 3D printing processes, stereolithography (SLA), laser sintering (SLS) and fused deposition modeling (FDM). When the patent for the FDM process expired in 2009, 3D printing was a hot topic in the media and the impression was created that this was a new innovation.

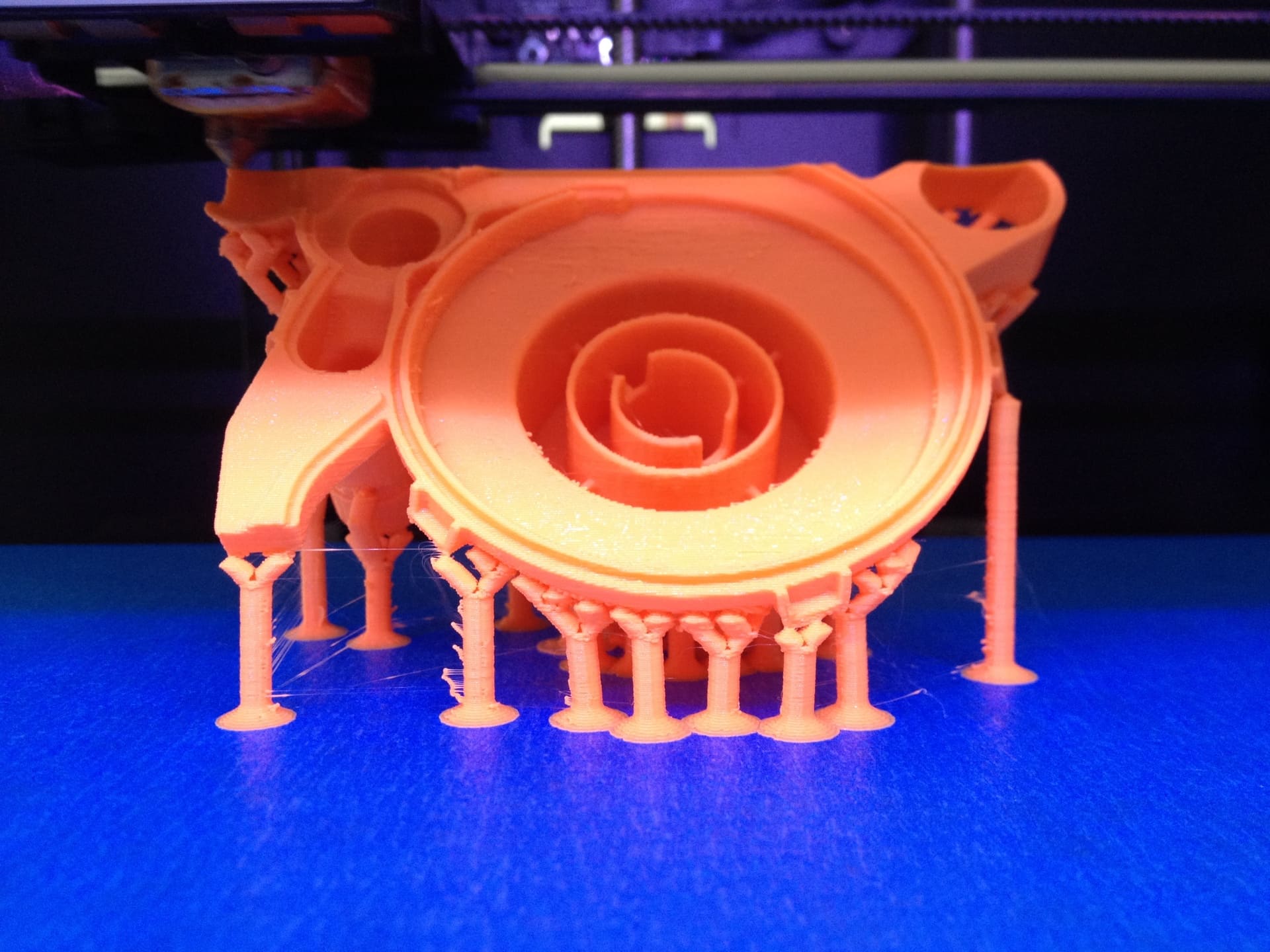

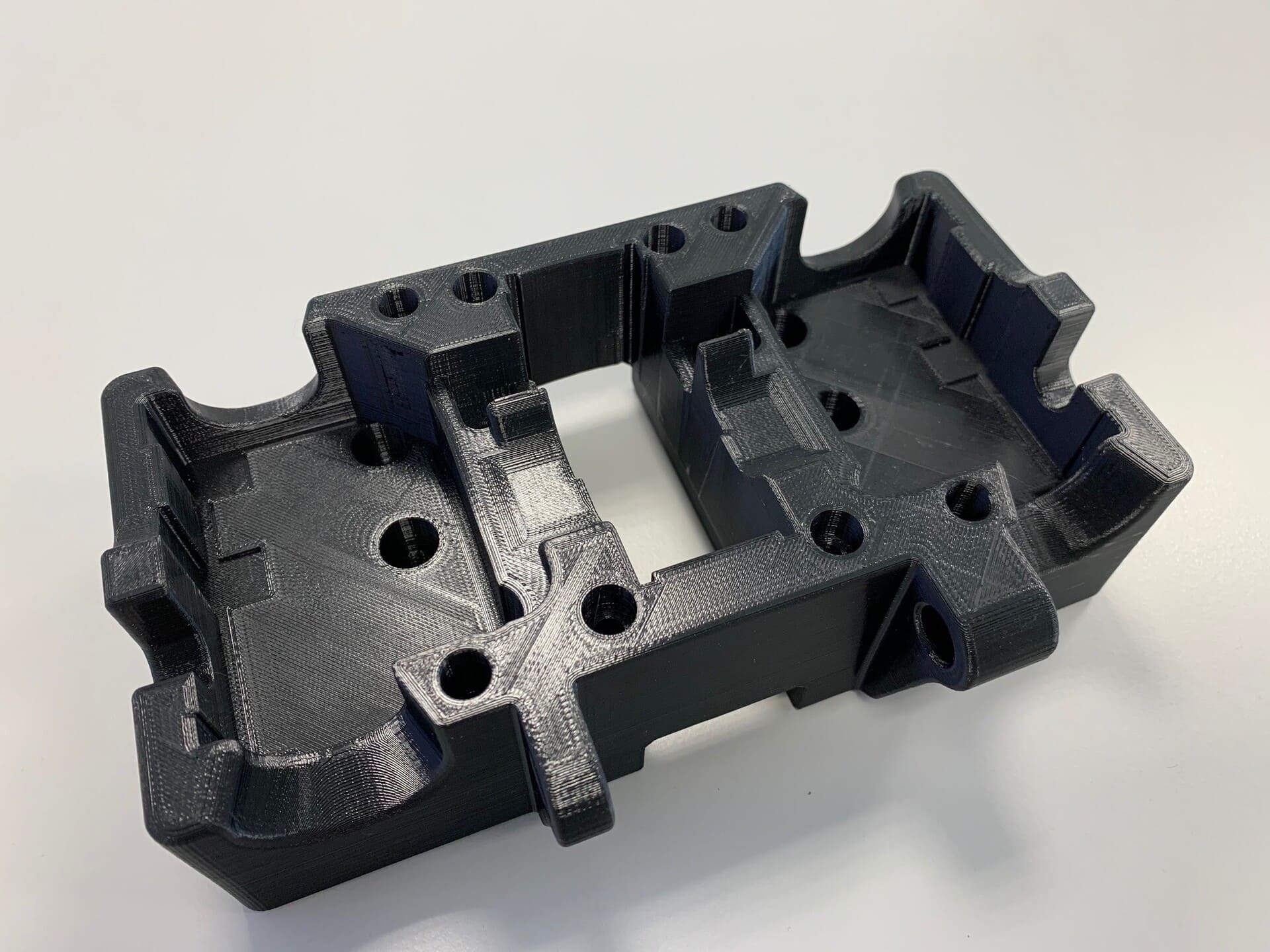

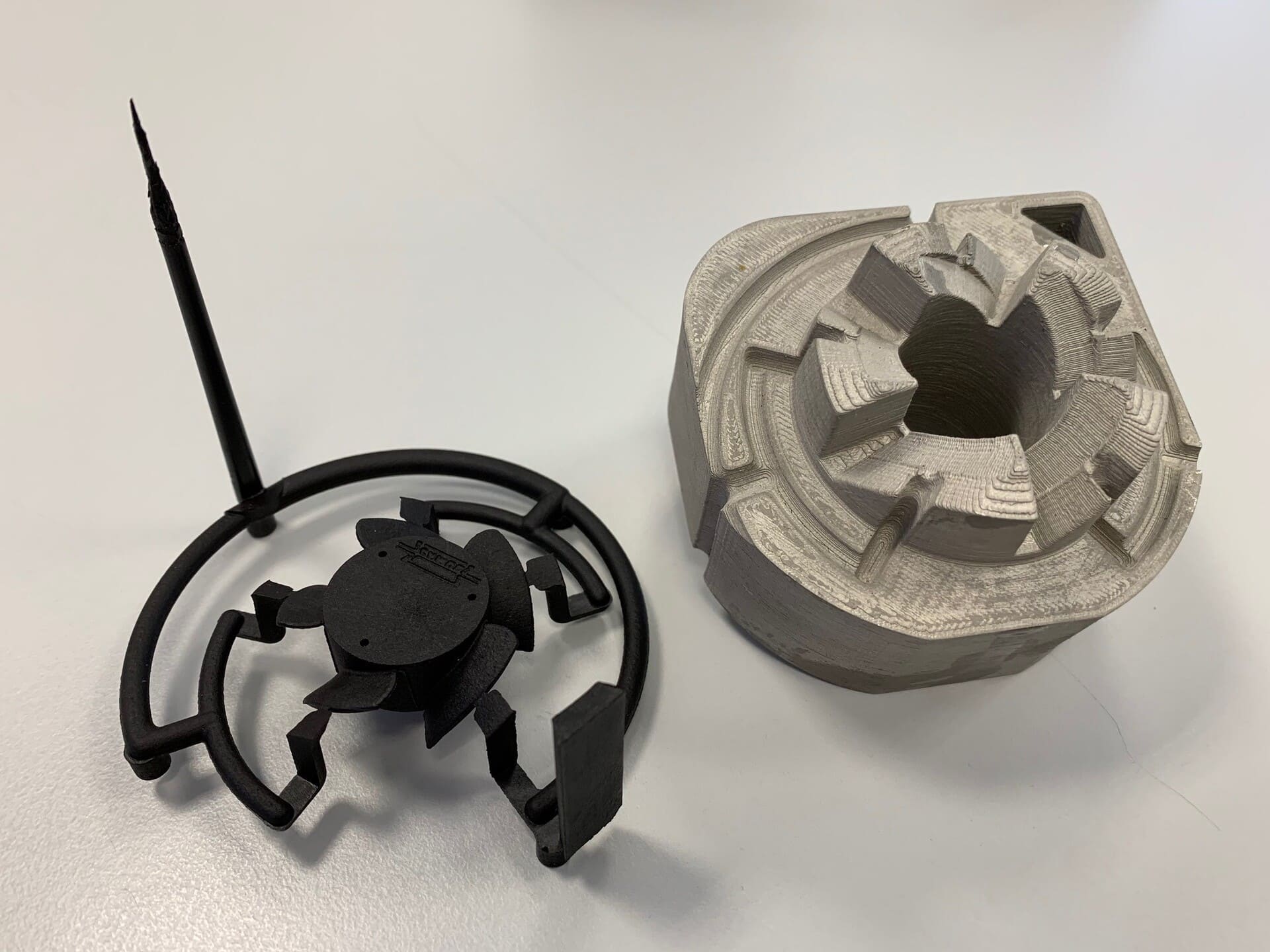

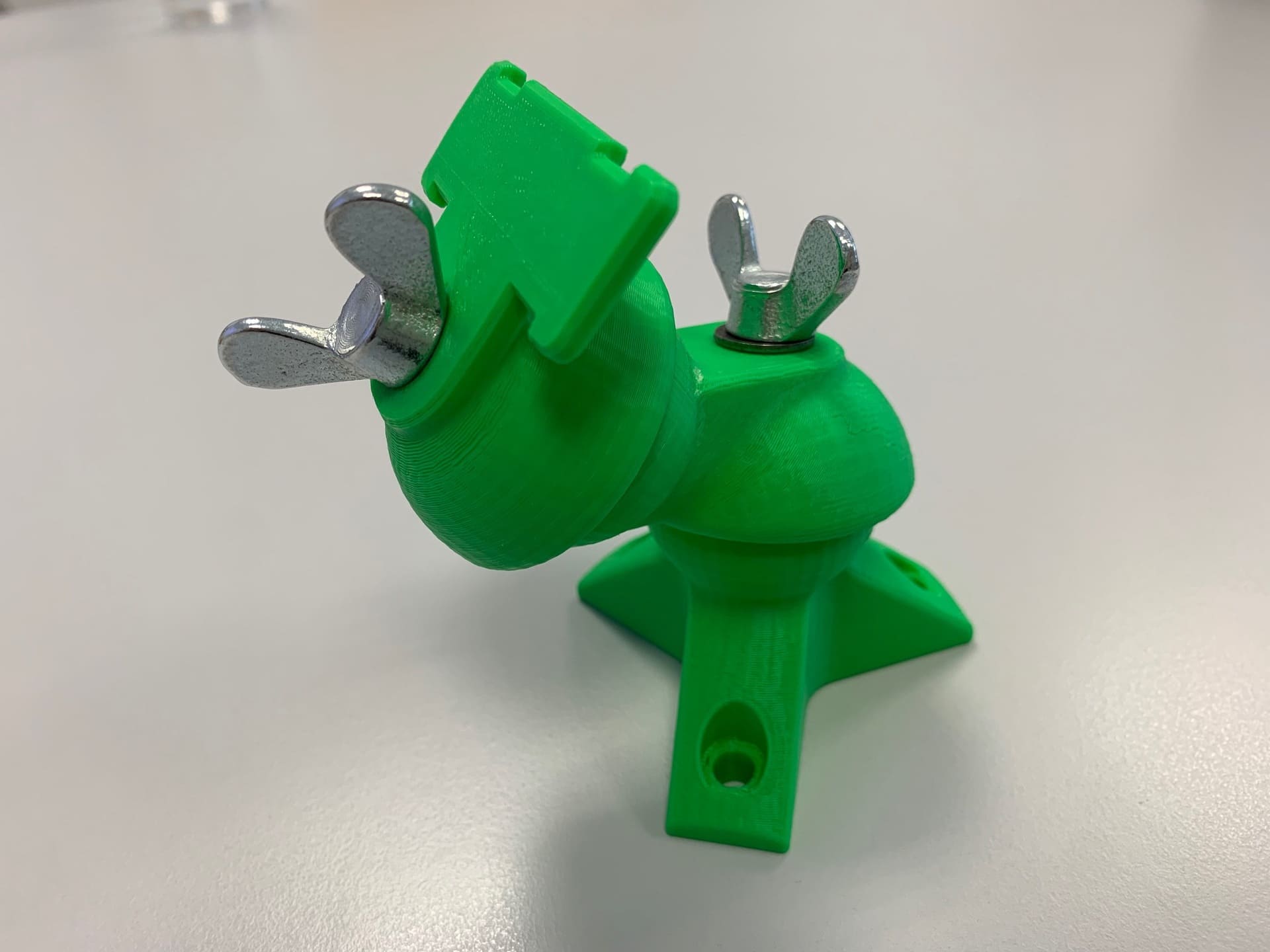

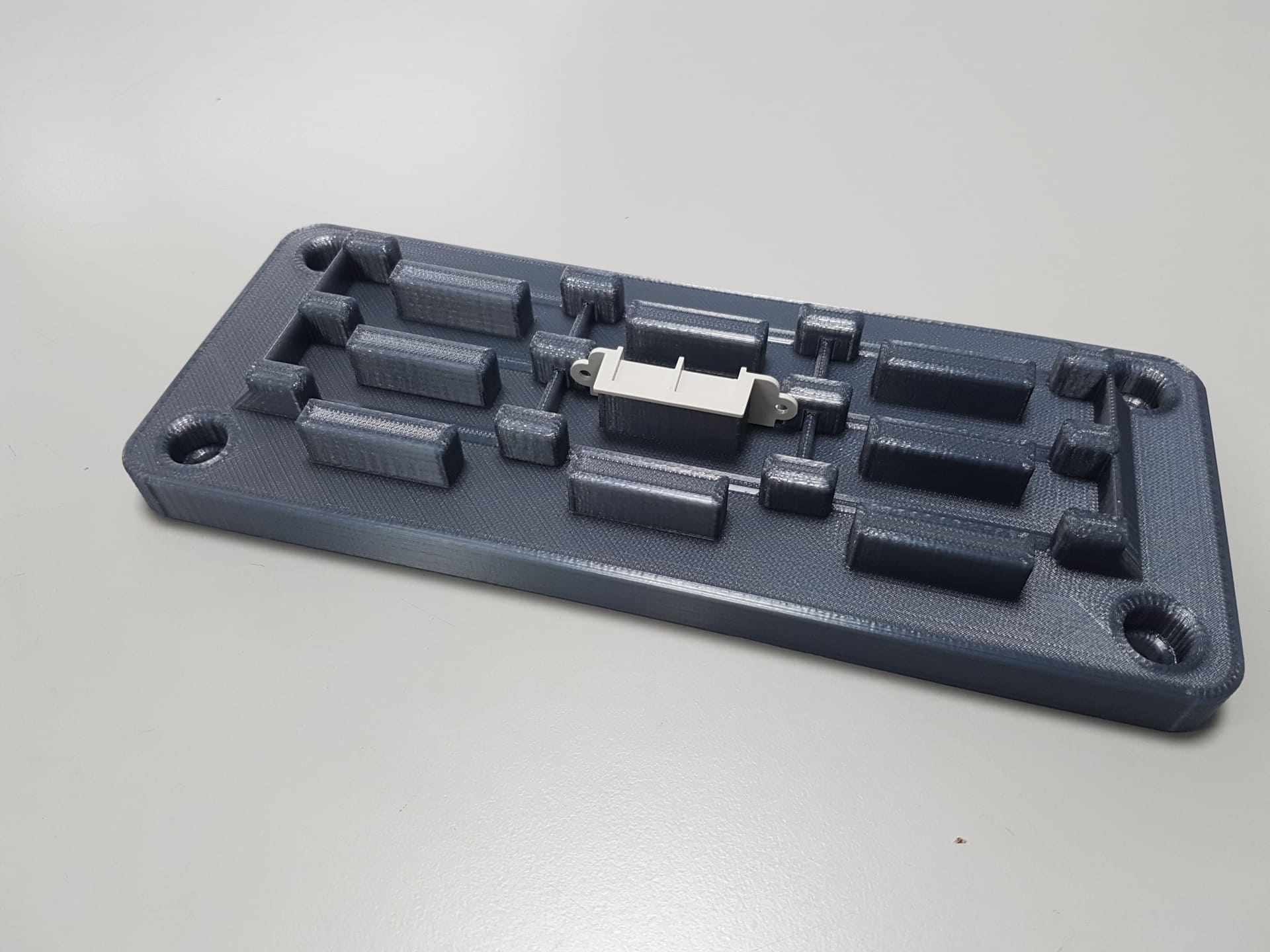

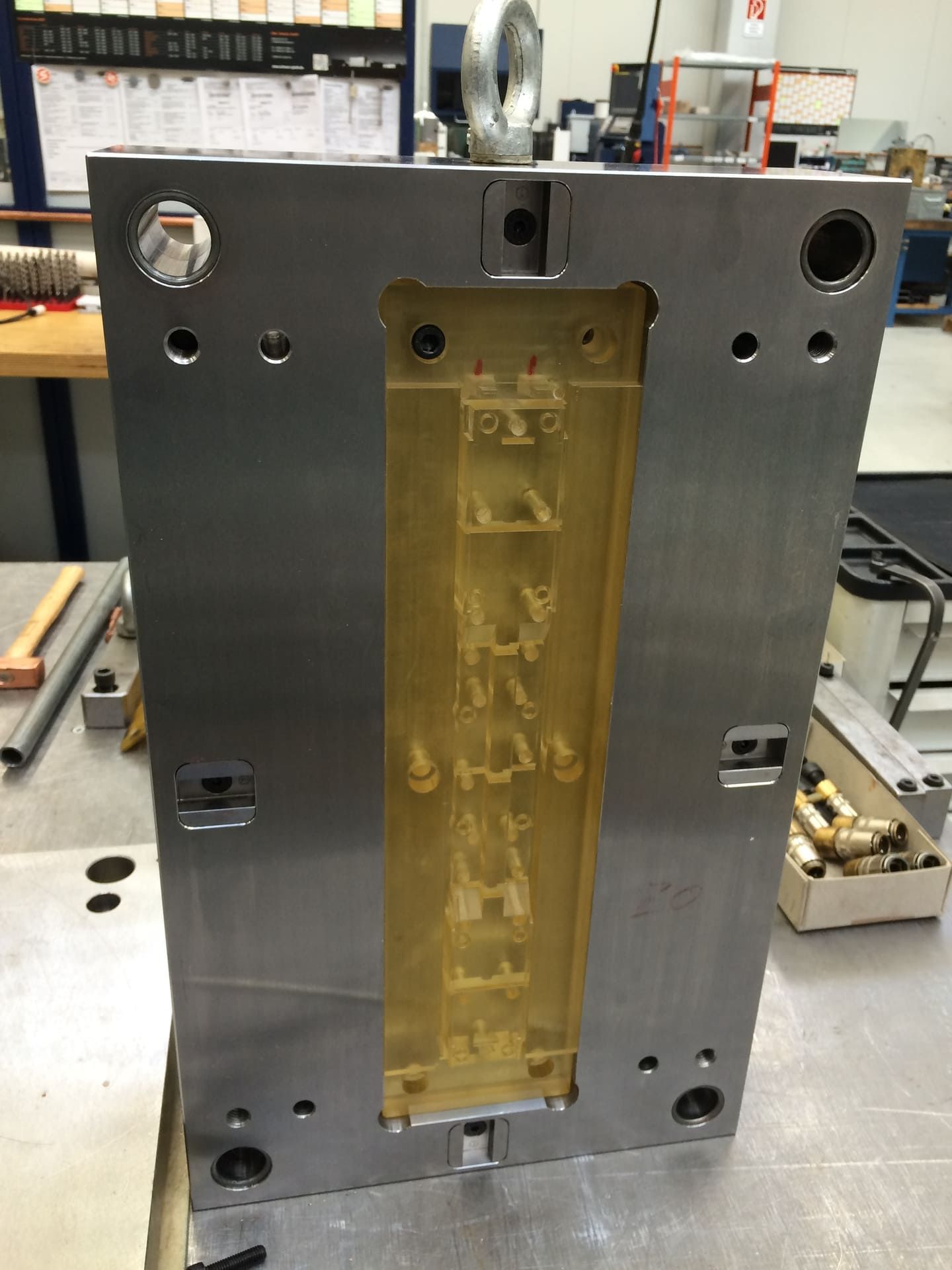

Schwarz GmbH has also been intensively involved with this technology and has established the first FDM printer in the company in 2014. A lot has happened since then, as 5 FDM printers and 1 DLP printer are now in almost continuous operation. The field of application at SCHWARZ is complex, whether it is fixture construction, handling systems, test gauges or special components, almost everything can be printed today. The range of materials is wide: PETG, PLA, ABS, TPU, glass fibre reinforced materials and photopolymers allow countless individual applications. At FAKUMA 2018, SCHWARZ presented a metal tool insert manufactured using the FDM process for the first time.

With generative manufacturing, geometries can be realized that could not be realized with conventional manufacturing methods until now. The topic of lightweight construction can also be excellently realized with honeycomb model structures. As a result, less material is required, production time is reduced and weight is saved, which is a great advantage, especially in the case of accelerated masses of our automation systems.

Generative manufacturing has massively changed the manufacturing processes in our equipment construction. Recently 2014 almost all fixtures were still being manufactured in the conventional way, but today 80% of the components are produced using 3D printing. Our printers are monitored by camera systems and can be controlled via a secure remote access. "Thus, the printers are used to maximum capacity and can also produce overnight or on weekends" - says Andreas Artmayer, head of the R&D department.