Parts quality and customer satisfaction come first

Within a period of only three months, the entire component assembly of Gebr. Schwarz GmbH was restructured.

Not only the assembly workstations, but also the material flow, the internal logistics and the production method were considered and optimized. Many suggestions for improvement from the project members and above all from the employees were taken into account, as they work on site and are therefore regarded as experts in their field.

The motivation for the restructuring was to increase customer and employee satisfaction and to eliminate waste in the process.

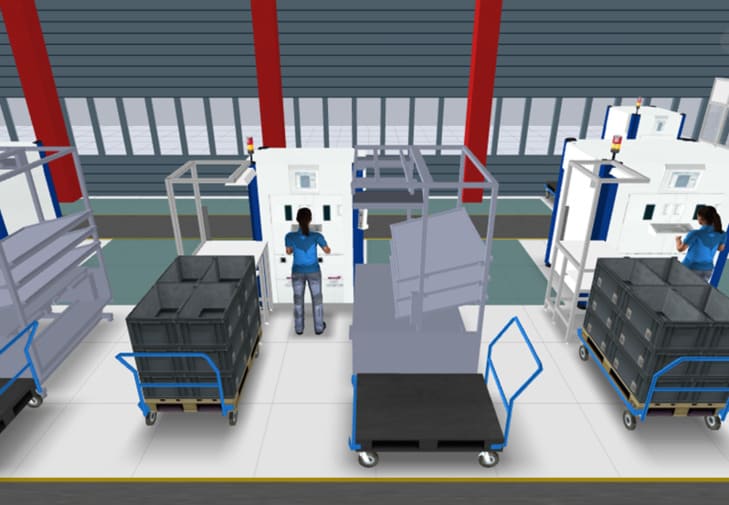

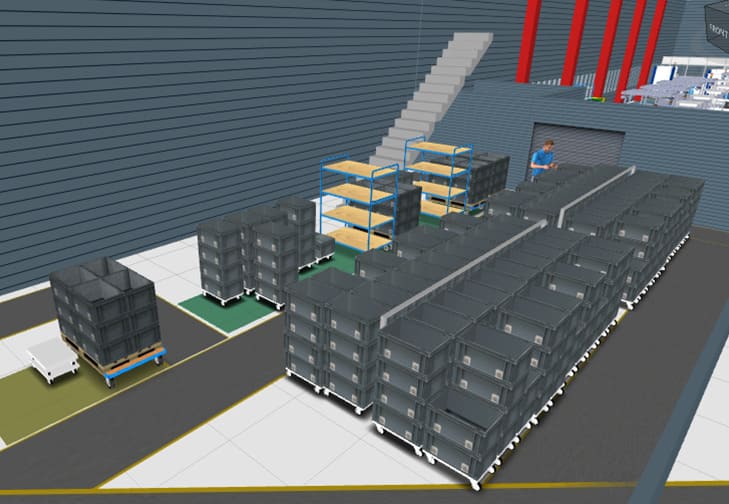

The first step was to analyze which articles Gebr. Schwarz GmbH produced with which properties. In other words, how many blanks are further processed, how large are they in volume, how many workstations are used to produce the assembly and how often are they shipped to the customer each year? By means of this analysis, internal shuttle packaging, new jobs, a supermarket principle and better material flows were developed. Schwarz GmbH has attached great importance to the fact that everything can be processed in one-piece flow at the individual workstations and that it is possible to combine individual workstations into assembly lines for more complex assemblies. Through one-piece-flow processing, the production of semi-finished parts could be eliminated and assembly errors reduced.

By separating value creation and logistics, employees can better focus on their actual activities, the assembly process, and are not distracted by logistics activities. At the end of the project, it can be stated that quality and added value have increased significantly and that employees can carry out their activities more conscientiously and relaxed thanks to structured processes and ergonomic work tables.