Calculation of heat transfer processes already in the early development phase

This close-to-reality simulation enables thermal optimization of the injection molding tool , even if no detailed mold has been designed yet.

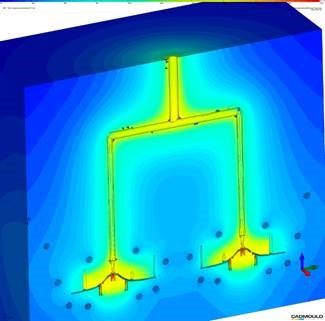

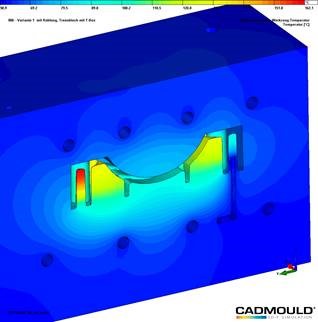

The software automatically create a mould sketch-arround the molded part and integrates the hot runner/cold runner gating system and the temperature control system. This provides the user with highly accurate insight into the heat transfer processes in the injection mold, which simulates the system in detail.

The flow processes in the cooling channel (temperature increase of the coolant, pressure loss, checking the turbulence, etc.) as well as the injection molding process over several cycles to the thermally stabilized state are calculated. The influence of hot runners on tool and component is considered as well. The heat exchange between tool and machine as well as the environment are also included in the calculation.

The result analysis provides information about thermal weak spots and optimization possibilities of the temperature control system.

Mold thermics is key to a stable injection molding process that can be reproduced over a long period. This leads to a sustained increase in quality, which reduces the susceptibility to failure.