Reproducible precision in injection molding

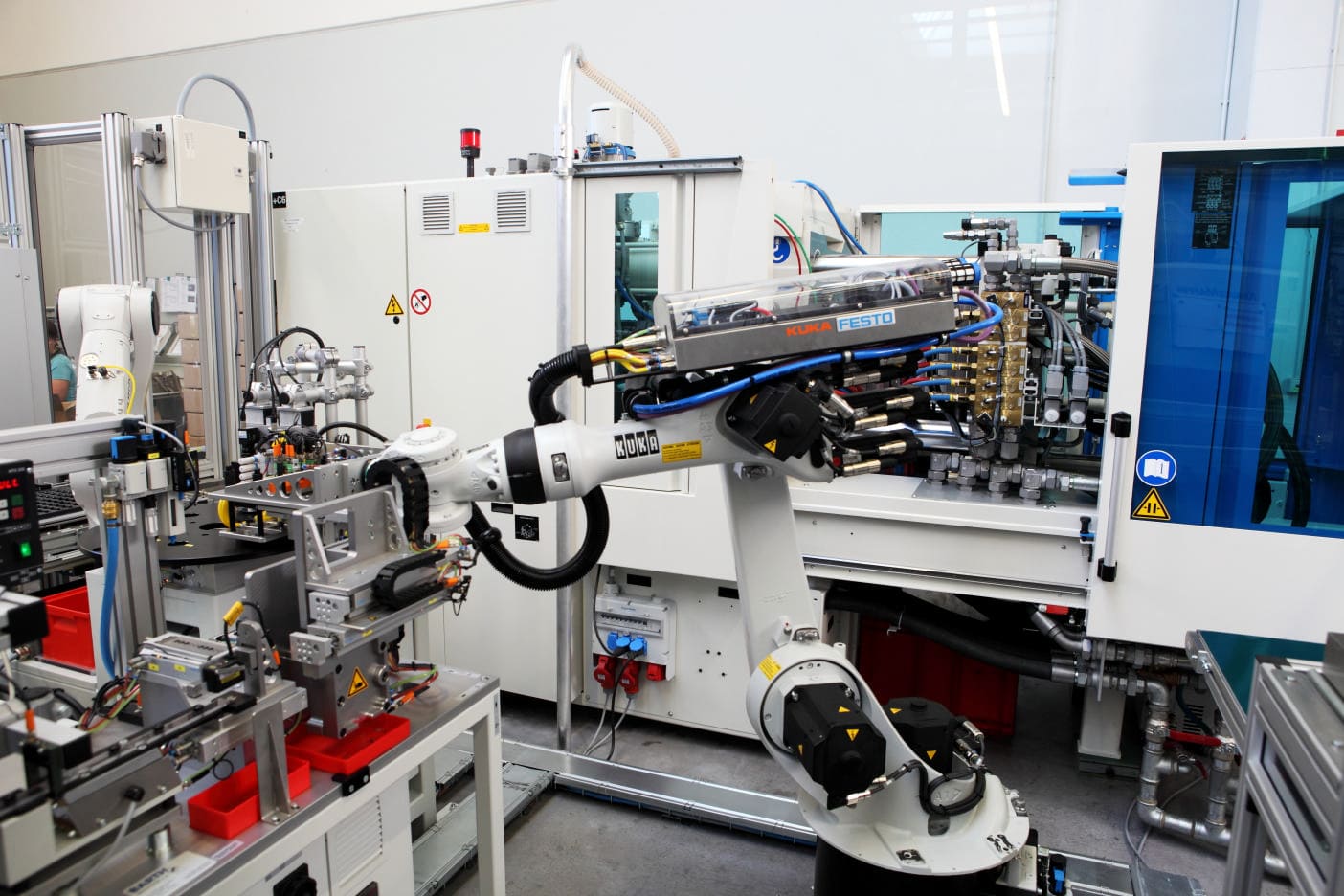

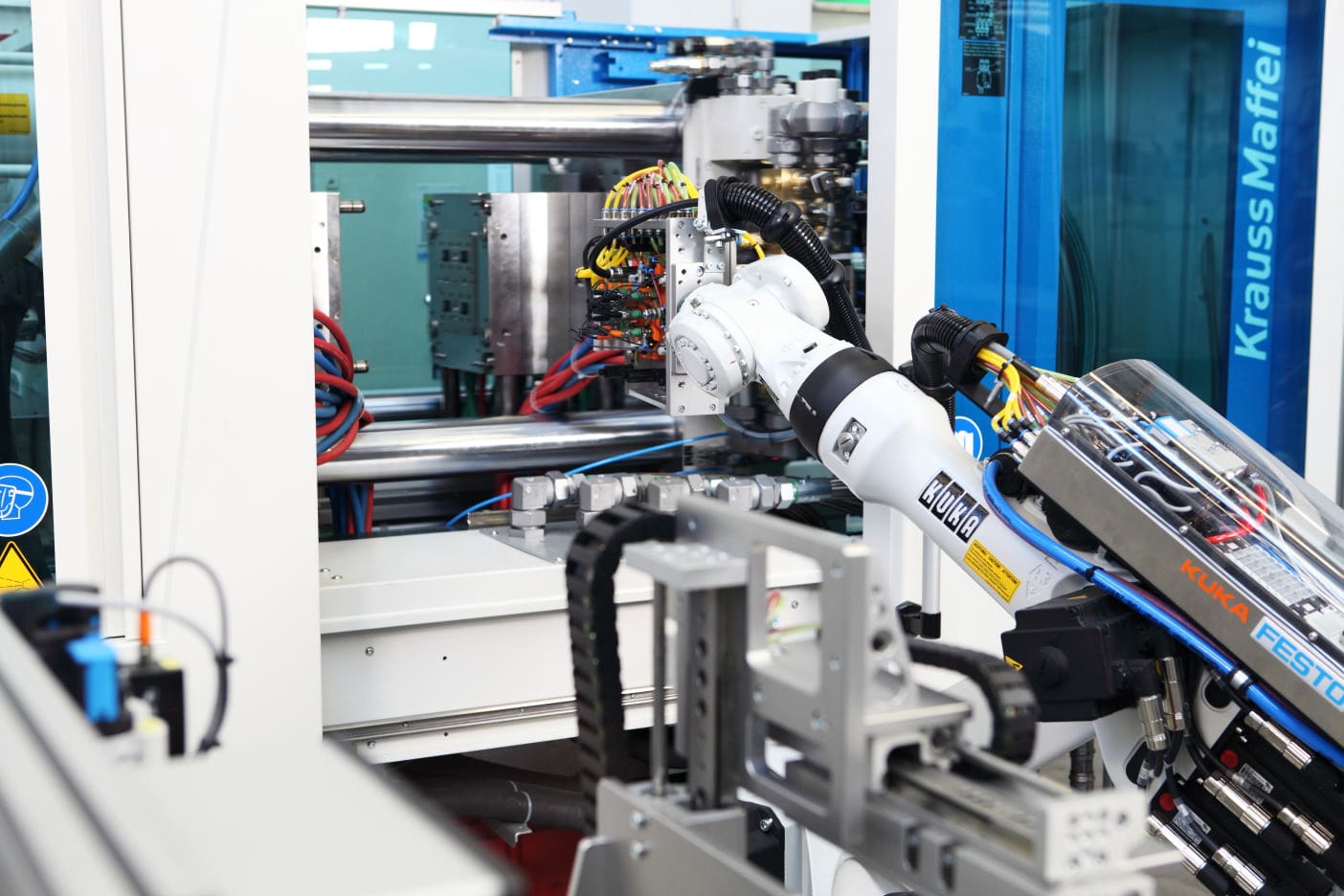

To supply customers with highest quality and efficiently manufactured products, Gebr. Schwarz invests continuously in modern production equipment and robotic systems. In addition to the already existing automation solutions from KUKA, a new production center with two parallel operating six-axle robots has been integrated.

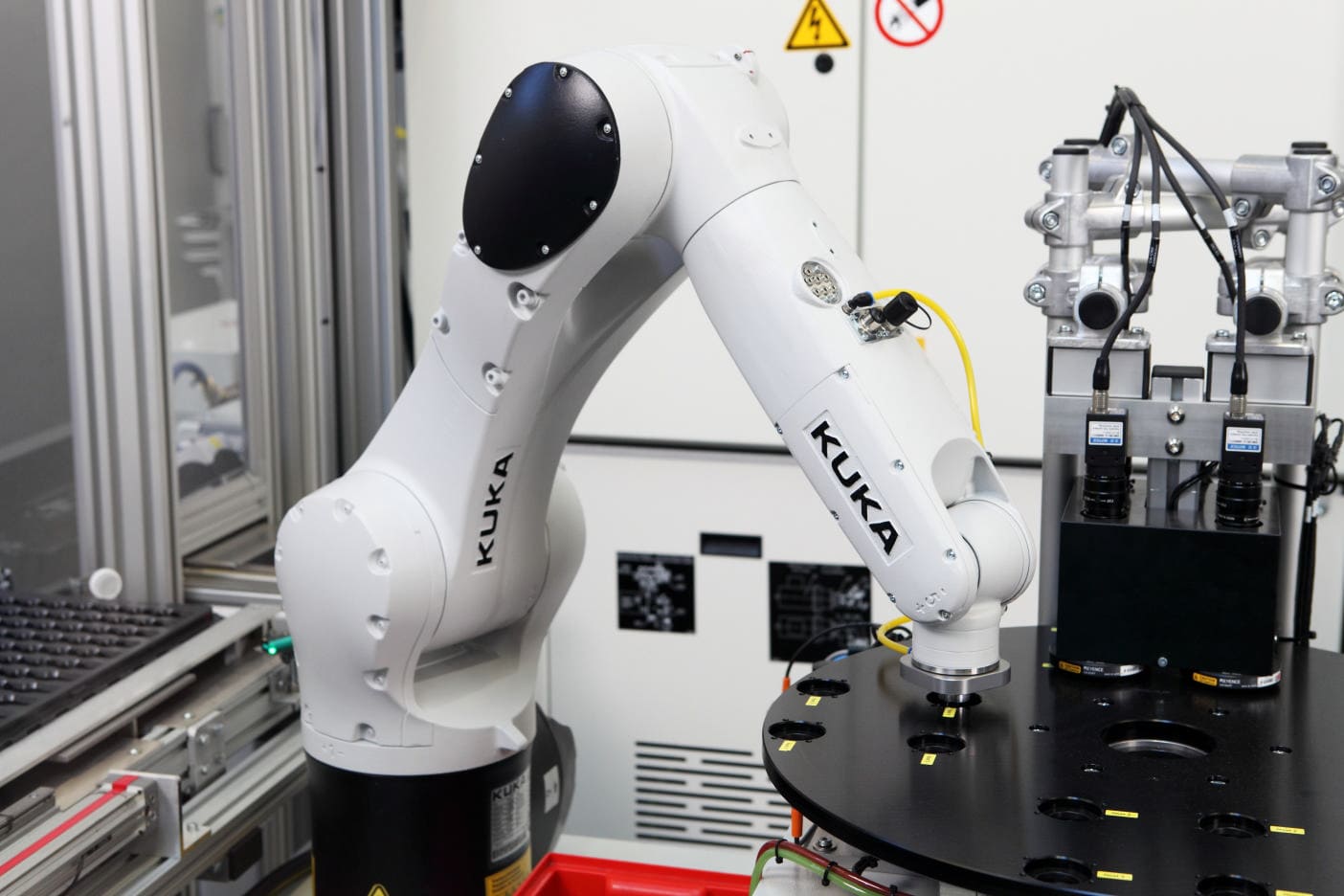

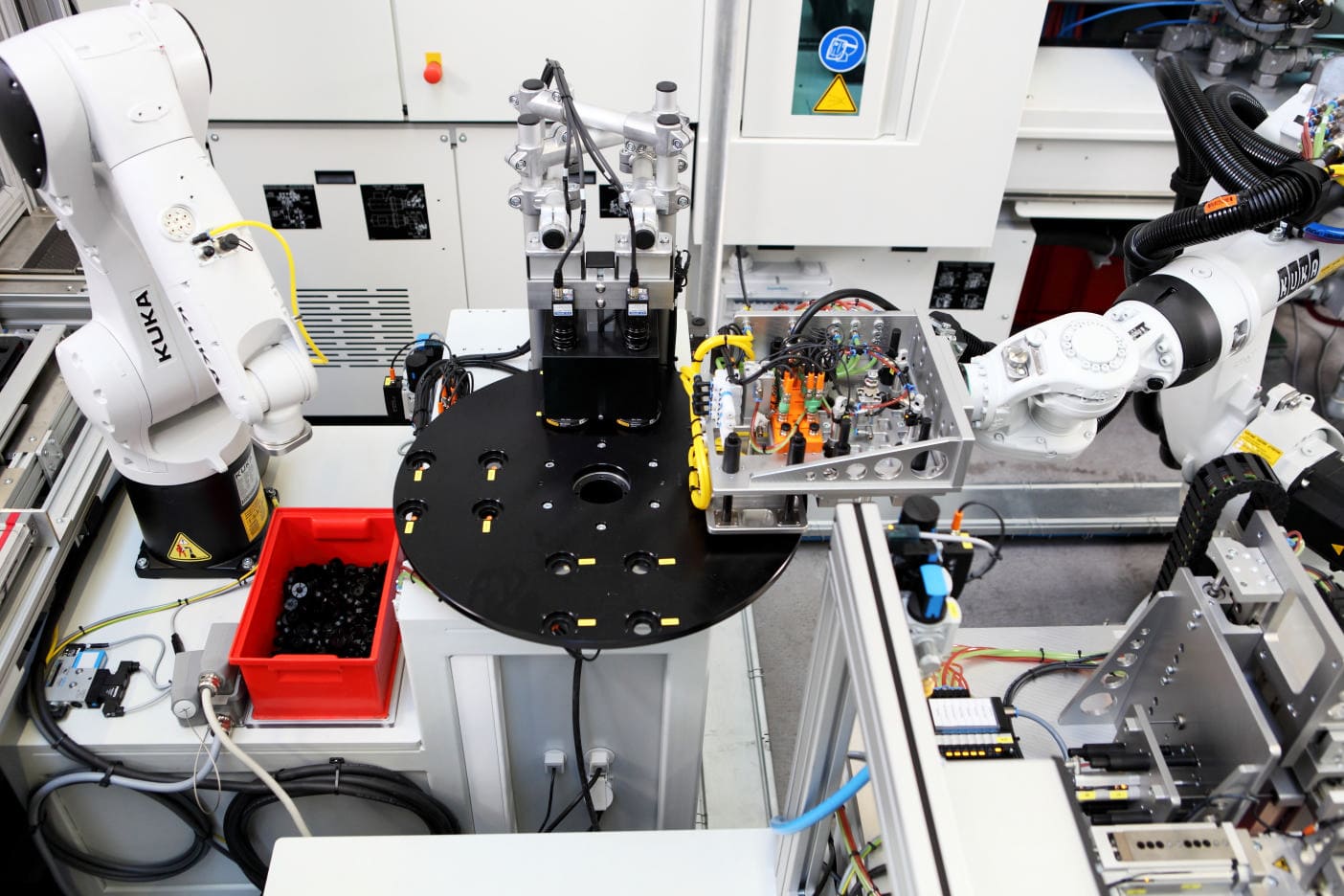

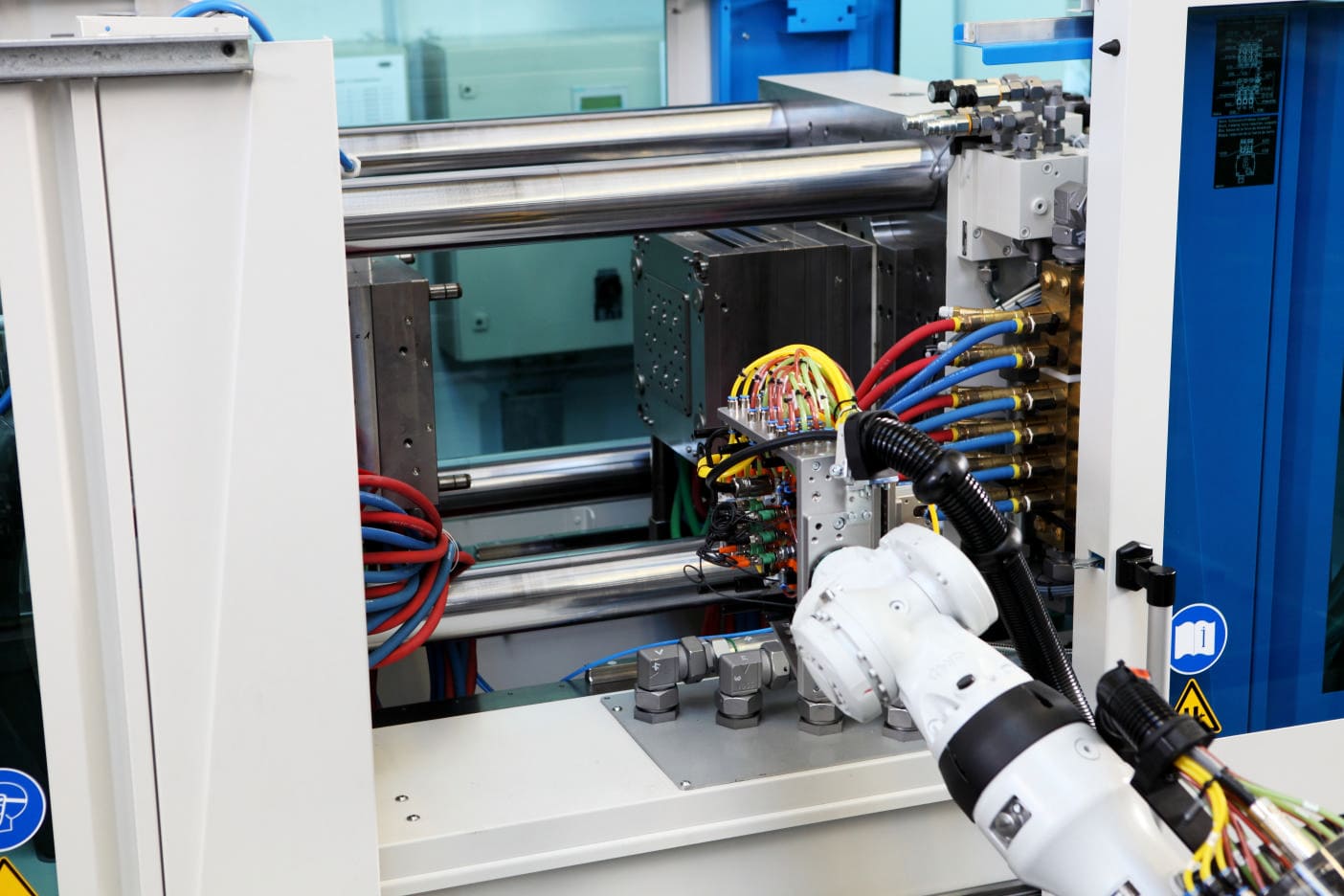

A KUKA KR 16 robot is utilized to manufacture small fans in high quantities within a 4 cavity tool. The insertion of very small shafts in the mold must be placed absolutely correct, for which a laser previously measure the exact position. After the injection molding process, the robot removes the finished fans from the tool and transfers them into an inspection station, where they are inspected automatically by a camera system. A small KUKA KR 6 then takes the final components individually from the test station and place them into palletized trays. "Only a robot can perform these process steps reliable. A human hand would cause corrosion on the components while touching them and with gloves the workers cannot grab the tiny parts" said Zlatko Roginic, production manager at the Gebr. Schwarz GmbH.

The production of complex injection molding parts requires a high degree of precision and repeatability. In addition, only a robot is capable to guarantee the predetermined cycle time and process safety.

In view of new automation technologies, the employees of Gebr. Schwarz were intensively trained in dealing with the new KUKA robot systems. "With such robot-based solutions, we will increase productivity significantly - by consistent high quality," said Roginic. The now realized technical solution also stands as a pilot project for similar challenges in the future.

A video of the automation system was supplied by KUKA on YouTube.